Description

MDI polyurethanes – the preferred insulant for energy efficiency

Polyurethane Insulation

Polyurethane is one of the most energy efficient insulation materials available in buildings and appliances. From homes to offices, polyurethane insulation can be used in roofs, walls, floors and ceiling cavities, as well as building exterior applications, in both new and retrofit construction projects. Polyurethane insulation is also used to improve the energy efficiency of refrigerators, cold storage facilities, commercial pipelines, water heaters and more.

With energy prices subject to significant volatility and the growing pressure to reduce carbon dioxide emissions caused by fossil fuels, the need for energy saving insulation is great.

Governments are recognizing this with new energy efficiency legislation. As a leading global producer of methylene diphenyl diisocyanate (MDI), a key component in polyurethane insulation, Huntsman plays a role in conserving energy and contributing to a sustainable planet.

Additionally, with the recent acquisition of the business of Oxid L.P., Huntsman now offers a full range of polyols, including TEROL® aromatic polyester polyols and JEFFOL® polyether polyols. Both of which are key components used in the manufacturing of numerous polyurethane-based insulation products/systems, including polyisocyanurate (polyiso/PIR) boards, spray polyurethane foam and insulated metal panels.

Polyurethane: the preferred insulant for energy efficiency

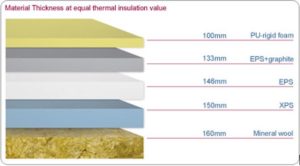

Polyurethane-based insulation has one of the highest thermal resistance (R-values) at a given thickness and lowest thermal conductivity of all insulation materials. Additionally, it can be used in many building types, where the need for insulation and air-tightness is combined with water vapor retardation, load-bearing strength, impact resistance, weight and space optimization, low maintenance and durability.

What is polyurethane insulation?

Polyurethane is formed by mixing an isocyanate, such as methylene diphenyl diisocyanate (MDI)with a polyol blend. These components are mixed to form a rigid, cellular foam matrix. The resulting material is an extremely lightweight polymer with superior insulating properties.

Insulation products, based on MDI, conserve energy in housing and commercial properties, and play a critical role in the food supply chain – keeping products at the right temperature in refrigerated vehicles, chiller cabinets and refrigerators. Polyurethane insulation products play an important role in addressing some of the emerging global megatrends, such as energy management.

Globally, about half the energy used in the life of a building is for heating and cooling, so effective insulation is a major priority.

Compared to other building materials, polyurethane insulation has the highest thermal resistance(R-values) at a given thickness and lowest thermal conductivity.

Use of polyurethane insulation products in residential and commercial buildings helps meet advanced energy codes, contributes toward green building certifications and provides comfort to the building occupants.

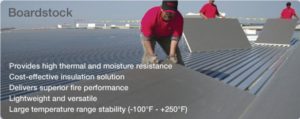

Boardstock

As a leading producer of methylene diphenyl diisocyanate (MDI), Huntsman works closely with customers that manufacture rigid foam insulation board (boardstock/insulation board and block) for residential and commercial construction applications. Boardstock can be faced (covered) with a wide variety of materials including paper, aluminum, kraft, fiberglass, gypsum, perlite, oriented strand board (OSB) and fiberboard.

Because of its light weight, boardstock can be easily installed as cavity insulation; on flat or pitched roofs or as insulated sheeting in timber-framed buildings. Depending on building requirements, boardstock can be cut into a variety of shapes and sizes. Additionally, it can be used for pipe insulation, industrial applications (tanks, fittings, valves), refrigeration applications, and for the transportation industry (refrigerated trucks).

Applications

- Commercial, residential and industrial

- Flat and pitched roofs

- Cavity walls and wall sheathing

Spray polyurethane foam

Spray polyurethane foam (SPF) is one of the fastest growing building insulation products globally. SPF can help reduce energy use in new and existing buildings. Up to 40 percent of U.S. energy demand is consumed by buildings, and according to the U.S. Department of Energy, as much as 40 percent of a building’s energy is lost due to air infiltration. SPF functions as both an insulation material and an air-sealing product. In buildings insulated with SPF, utility cost savings of up to 50 percent can be achieved.

Huntsman’s methylene diphenyl diisocyanate (MDI) is used as the “A-side” ingredient in many SPF systems. Additionally, Huntsman offers a full range of SPF raw materials including polyols, catalysts and other additives used to formulate the “B-side” of SPF systems.

What is spray polyurethane foam (SPF)?

Spray polyurethane foam (SPF) is an insulation that also functions as an air barrier and depending on type, as a bulk water barrier and moisture vapor retarder. SPF is made by reacting methylene diphenyl diisocyanate (MDI) (A-side or iso) with a polyol blend (B-side or resin). The two liquid components are joined under pressure in a spray nozzle where they are applied directly onto wall, roof or building assembly. Once the reacting liquid hits a surface, it expands 30 to 120X and solidifies into a foam matrix. SPF is typically applied by certified professionals.

SPF seals and protects the building from infiltration of hot air, cold air, moisture and sound. Its R-value reduces conductive heat transfer and its air barrier properties help reduce convective heat transfer. SPF is an ideal insulation product for residential, commercial, institutional, military and industrial buildings. According to the U.S. Department of Energy (DOE), utility cost savings of 30 to 50 percent can be realized with SPF insulation.

SPF benefits in buildings

- Offers higher thermal resistance, can reduce heat transfer and lowers utility costs

- Reduces air infiltration, can reduce energy losses and lower utility costs

- Through vapor retardation, can prevent moisture in the walls and reduces condensation and mold

- Restricts unwanted dust, pollen, allergens, etc. from entering, and can improve indoor air quality

- Can reduce HVAC (heating, ventilation and air conditioning) equipment needs by 50 percent (due to reduced heating and cooling demands), and lower equipment costs

Helps meet building codes and contribute to green building certifications, including:

- LEED®-H for homes and LEED® for commercial buildings

- BREEAM®

- ASHRAE Standard 90.1

- Deutsche Gesellschaft für Nachhaltiges Bauen e.V. (DGNB)

- ENERGY STAR®

- Haute Qualité Environnementale (HQE)

- International Energy Conservation Code (IECC)

- US Army Corps of Engineers Building Air Tightness Requirements (ECB 2009-29)

- National Association of Home Builders Green Building Standard™ for homes

Types of SPF

Open cell SPF (8kg/m3 or 1/2lb./ft.3 density) has a thermal conductivity less than 39mW/MK. It is an effective insulant that is typically installed in wall cavities, attics and crawl spaces. It acts as both an air barrier and noise absorber. Open cell SPF is softer and more flexible than rigid closed cell foams. In general, it is best suited for mixed or warm climates. It can be used in colder climates when installed in combination with a vapor retarder.

Closed cell SPF (32-48 kg/m3 or 2-3lb./ft.3 density) has a thermal conductivity less than 24 mW/MK. It is an excellent air barrier, bulk water barrier and moisture vapor retarder. It provides structural enhancements to buildings, and is effective in all climates. It is typically installed in wall cavities, attics, basements, crawl spaces or on a building’s exterior walls.

New construction and retrofit applications

In new construction applications, SPF creates a thermally-effective, tight building envelope. The result is a reduction in energy loss due to air infiltration, and significantly lower heating and cooling costs for the homeowner or building owner. According to the DOE, air infiltration can account for up to 40 percent of a home’s heating and cooling costs. The thermally-efficient building envelope allows for a reduction in the size of the HVAC equipment required to maintain comfortable air quality in the home or building.

SPF restricts the infiltration of moisture, outdoor allergens and pollutants into a building, resulting in improved indoor air quality. Some types of closed cell SPF are GREENGUARD Indoor Air Quality Certified® and GREENGUARD Children and SchoolsSM Certified.

In retrofit applications, energy performance improvements have been measured in buildings when SPF is applied to the unvented roof deck, attic floor, crawlspaces, basements, ceilings and rim joists.

Applications

Spray polyurethane foam (SPF), available in open cell and closed cell, provides an effective, tight thermal and air barrier around a building’s envelope. This results in a reduction in energy loss due to air infiltration, and significantly lowers heating and cooling costs.

Energy efficiency and green building practices are at the forefront of new home/building construction and retrofit projects. SPF helps architects and builders design and build more energy efficient homes/buildings, thus allowing the building owners to reduce their energy consumption and costs.

SPF is an ideal insulant for residential, commercial, institutional, military and industrial buildings.

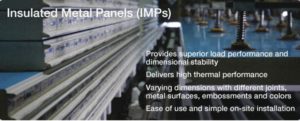

Insulated Metal Panels (IMPs)

Insulated Metal Panels (IMPs) have a rigid methylene diphenyl diisocyanate (MDI)-based polyurethane foam core “sandwiched” between two metal facings. Panels are factory produced on a continuous lamination basis with metal facings – usually steel– encapsulating a foamed PUR or PIR core. The thickness of the polyurethane foam can range from 30mm to 240mm depending upon application and required insulation characteristics. These versatile products are also known as sandwich panels.

In Europe, DaltoPUR® and DaltoPIR® insulation foam from Huntsman has been designed to improve the manufacture of the panel and has achieved the following fire resistance classifications, according to European Standard EN 13501-2:

- EI 30 for 100 mm wall panels (EN 1364-1)

- REI 30 for 100 mm roof panels (EN 1365-2)

Versatile Applications

Because of their high thermal insulation values, ease of use, high degree of stability and rigidity, IMPs are used in a diverse range of applications such as:

- Commercial and industrial buildings

- Self-supporting roofs and walls

- Commercial and residential entry and garage door panels

- Commercial refrigeration

- Refrigerated transport vehicles

Structural Insulated Panels

Structural insulated panels (SIPs) have a rigid methylene diphenyl diisocyanate (MDI)-based polyurethane foam core between two pieces of oriented strand board (OSB) or similar material. These lightweight panels provide superior wall and roof strength to the construction industry, while delivering energy efficiency.

SIPs provide a higher thermal insulation R-value (resistant value) per unit thickness when compared to stud walls constructed with traditional sheetrock and fibrous insulation. Designed for ease-of-use at construction sites, SIPs can be factory fabricated to fit any commercial or residential building design.

Applications

- Commercial buildings

- Residential properties

- Walls

- Roofs

Appliances and commercial refrigeration

When used in appliances and commercial refrigeration applications, polyurethane insulation can help reduce energy loss by restricting heat and cold infiltration. This type of insulation also greatly enhances structural integrity and retards water and moisture, thereby increasing the longevity of any of the products where it is used.

Created by injecting a well-mixed liquid formulation containing polymeric methylene diphenyl diisocyanate (MDI) and a MDI-reacting polyol blend into a shell or cavity, polyurethane insulation can be found in a variety of appliance applications, including refrigerators, freezers, water heaters, picnic coolers and more. Additionally, polyurethane insulation is also used in commercial and residential entry and garage doors.

Food Chain

Approximately 50 percent of the world’s food would rot without insulated refrigeration. Growing urban populations require massive investment in the storage, transportation and processing of perishable foods under controlled temperature conditions. Due to their thermal, processing and hygienic advantages, polyurethane/polyisocyanurate insulation are by far the most widely used insulants for refrigeration.

Applications

- Refrigerators and commercial refrigeration systems

- Water heaters

- Coolers

- Commercial and residential entry and garage doors

Pipe insulation

Polyurethane insulation for pipes prevents heat loss and in cold climates helps maintain a warmer pipe temperature to avoid freezing or cracking. Pipe insulation provides a high mechanical strength and flexibility in a variety of applications including oil and gas pipelines, district water pipes and industrial tanks.

Compatibility with polyethylene, polypropylene, high density polyethylene and PVC pipe materials, methylene diphenyl diisocyanate (MDI)–based polyurethane foam is suitable for pipe applications ranging from 0.5 inch/12.700 mm diameter plumbing pipes up to district heating pipes with an 80 inch/2032 mm diameter and 10 inches/254 mm of insulation. Pipe insulation helps engineers optimize the efficient performance of a pipe network, making it easier to manage operational and capital costs.

Applications

- Offshore and on-shore oil and gas pipelines

- District heating and cooling pipes

- Pipes in food, chemical, energy, steam and solar industries

- Industrial tanks

Detaylı bilgi için;

https://www.huntsman.com/polyurethanes/a/Products/Insulation

Discontinuous Systems:

Cold Room Panel Systems:

Emapol 29 DP 23 & Emanat 200

Aisle Type Cabinet Systems:

Emapol 30 DP 23 & Emanat 200

Decorative Polyurethane Systems:

Emapol 16 WI 01 & Emanat 200

Emapol 12 WI 01 & Emanat 200

Emapol 11 WI 01 & Emanat 200

Wood Imitation Systems:

Emapol 14 WI 01 & Emanat 70

Window Shutter Systems:

Emapol 39 WS 23 & Emanat 200

Pipe Insulation Systems:

Emapol TE 44204 & Emanat 200

Boiler, Tank Polyurethane System:

Emapol 10 SS 23 & Emanat 200

Emapol 12 SS 23 & Emanat 200

Solar Energy Systems:

Emapol 11 SS 23 & Emanat 200

Block Casting Panel Systems:

Emapol 19 PIR 45 & Emanat 200

Emapol 19 PIR 85 & Emanat 200

Refrigerator Polyurethane Systems:

Emapol 18 APP 50 & Emanat 200

Steel door & Mobo Polyurethane Systems:

Emapol 29 DCP 22 & Emanat 200

Ceramic Mold Polyurethane Systems:

Emapol 15 WI 01 & Emanat 200

Spray Polyurethane Foam Systems:

Emapol 18 SP 22: 30 Density closed cell spray polyurethane system

Emapol 22 SP 22: 25 Density closed cell spray polyurethane system

Emapol 10 PF 23: 10 Density open cell spray polyurethane system

Emapol 10 SI 23: 36 Density closed cell casting spray polyurethane system

Polyurea Systems:

Emapol Polyurea S 100: Pure Polyurea system

Emapol Polyurea H30: Hybrid Polyurea system

Emapol PUR 100: Two-component Polyurethane system

Primer Systems:

Emapol Primer EP 2606 : Pure Epoxy Primer

Emapol Primer EP 1012 F: Epoxy Filled Primer

Emapol Primer EP 2209 W: Moisture Barrier Epoxy Primer

Emapol Topcoat UVR 300: Topcoat

PDF download

PDF download